Improving engineering productivity and efficiency requires an understanding of a team’s strengths and weaknesses. Proper assessment makes strategic task distribution and optimal resource utilization possible, guaranteeing that tasks are in line with individual capabilities. Planning for engineering capacity is essential to increasing team output.

Nevertheless, most teams find it difficult to use engineering capacity planning effectively, which results in missed deadlines, burnout, and technological debt. This article examines the true meaning of engineering capacity planning, the reasons why teams usually make mistakes, and effective implementation techniques.

What Is Engineering Capacity Planning?

Engineering capacity planning is the systematic process of determining the production capability needed by a team to meet changing demands. Unlike traditional capacity planning models from manufacturing, software development must account for the creative and unpredictable nature of building software, considering:

- Team composition and skillsets

- Technical complexity of tasks

- Interdependencies between workstreams

- Unplanned work (bugs, incidents, technical debt)

- Learning curves for new technologies

- Collaboration overhead

Effective capacity planning doesn’t just ask, “Can we build this?” but rather, “How can we sustainably deliver value given our constraints?”

At its core, capacity planning involves:

- Understanding your team’s capacity: Knowing how much work your team can realistically handle.

- Forecasting future work: Anticipating upcoming projects, maintenance, and unexpected issues.

- Matching capacity to demand: Allocating resources effectively to meet current and future demands.

Types of Capacity Planning

Usually, most organizations use a combination of long-term, medium-term, and short-term capacity plans.

- Long-term planning (strategic): Organizational roadmap spanning 1-2 years, identifying major initiatives and talent requirements. Reviewed quarterly to maintain alignment with business objectives.

- Medium-term planning (tactical): Translation of strategic goals into executable action plans for the coming months. Monthly reviews enable adjustments based on changing priorities.

- Short-term planning (operational): Management of day-to-day engineering activities, addressing immediate needs through daily stand-ups and weekly planning sessions.

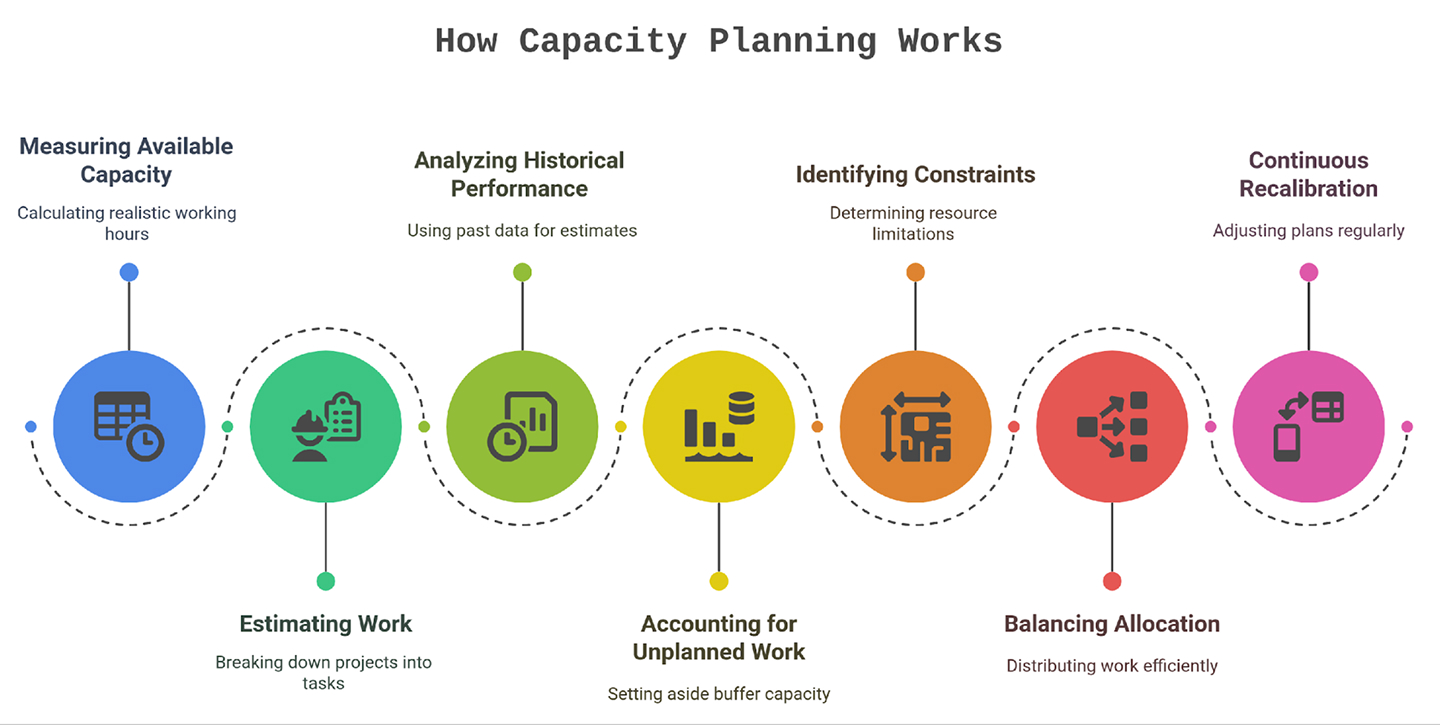

How Capacity Planning Works

The process of engineering capacity planning follows several key steps:

- Measuring available capacity: Calculating realistic working hours while accounting for meetings, administrative tasks, and other non-development activities.

- Estimating work: Breaking down projects into manageable tasks and estimating their complexity and effort requirements.

- Analyzing historical performance: Using past velocity and completion rates to calibrate future estimates.

- Accounting for unplanned work: Setting aside buffer capacity for interruptions, bugs, and production issues.

- Identifying constraints: Determining which resources (people, skills, tools) limit throughput.

- Balancing allocation: Distributing work to optimize for efficiency while preventing burnout.

- Continuous recalibration: Regularly reviewing actual vs. planned capacity and adjusting plans.

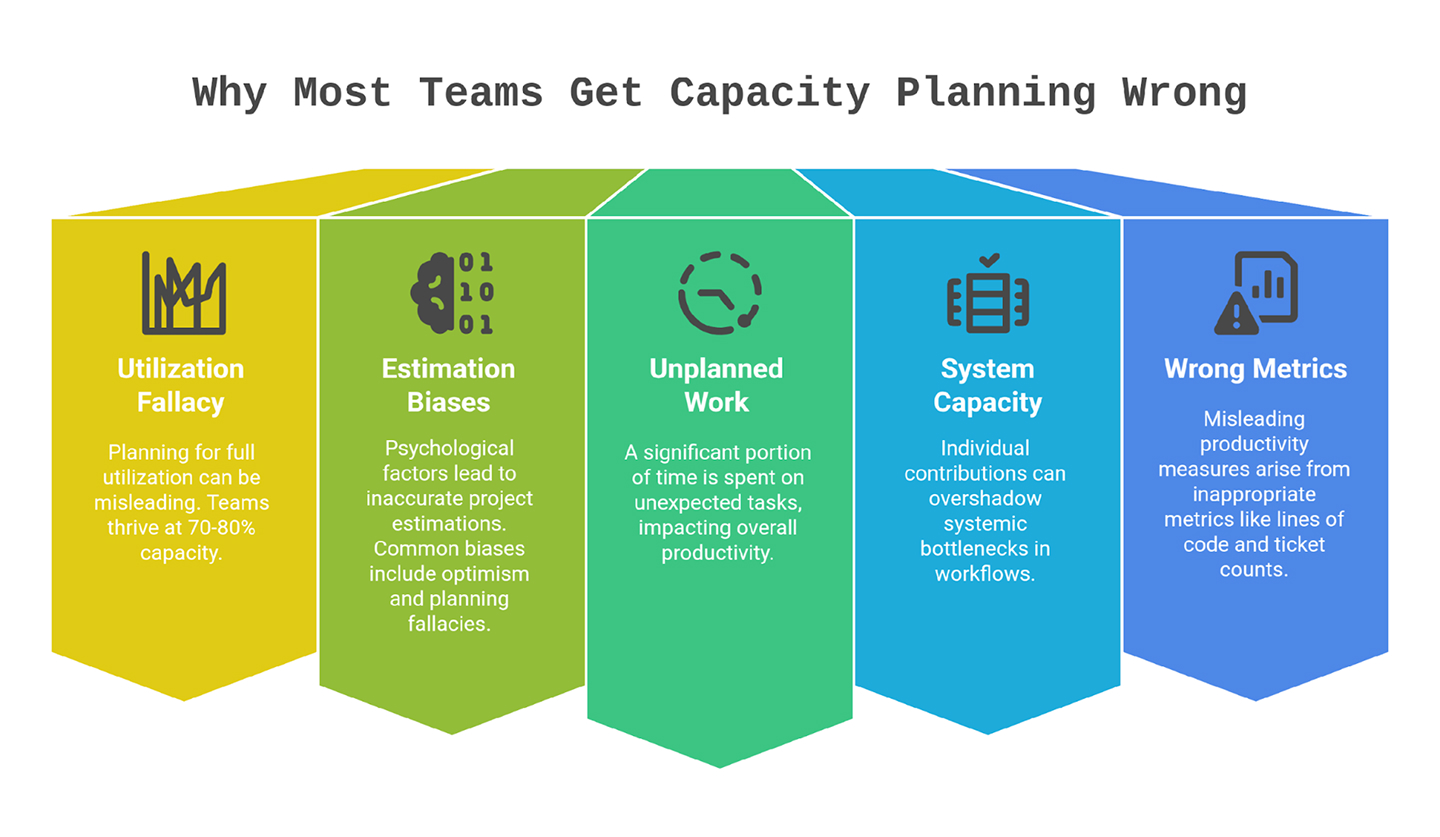

Why Most Teams Get Capacity Planning Wrong

Despite best intentions, many engineering organizations struggle with capacity planning. Here are the most common pitfalls:

1. The Utilization Fallacy

Many teams make the critical mistake of planning for 100% utilization. This approach fails to account for:

- Context-switching costs: Engineers lose up to 20% of their productivity when switching between tasks.

- Recovery time needed: Creative problem-solving requires mental recovery periods.

- Collaboration overhead: More complex projects require more communication.

- Unexpected challenges: Technical problems rarely follow linear solutions.

The reality: Teams running at 70-80% capacity often outperform those pushed to 100%, delivering more reliable estimates and maintaining higher quality.

2. Estimation Biases

Human psychology makes us inherently poor estimators. Teams consistently fall victim to:

- Optimism bias: Underestimating complexity and overestimating productivity.

- Planning fallacy: Failing to account for past experiences with similar tasks.

- Anchoring effect: Being influenced by initial numbers suggested in planning.

- Expert blind spots: Experts often underestimate the difficulty of complex tasks they find easy.

3. Neglecting Unplanned Work

The average engineering team spends 30-50% of their time on work that wasn’t explicitly planned, such as:

- Handling production incidents

- Addressing critical bugs

- Supporting other teams

- Addressing technical debt

- Upgrading dependencies and security patches

Teams that don’t budget for this reality find their carefully crafted plans quickly derailing.

4. Overvaluing Individual Capacity vs. System Capacity

Many capacity planning approaches focus exclusively on individual developer capacity while ignoring system-level constraints, including:

- Code review bottlenecks

- Testing and QA limitations

- Deployment pipeline constraints

- External dependencies

- Cross-team coordination requirements

5. Using the Wrong Metrics

Teams often optimize for misleading metrics, such as:

- Lines of code (quantity over quality)

- Number of tickets closed (incentivizes smaller, simpler tickets)

- Hours worked (rewards presenteeism over productivity)

- Story points without calibration (subject to inflation)

Key Strategies and Best Practices for Effective Capacity Planning in Software Development

Implementing effective team capacity planning requires a fundamental shift in approach. Here are key strategies that successful teams employ:

1. Embrace Collaborative Capacity Planning

Collaborative capacity planning brings together various stakeholders, such as engineers, product managers, designers, and operations, to create a shared understanding of capacity limitations and tradeoffs.

This approach:

- Surfaces constraints earlier in the planning process.

- Creates buy-in and shared ownership of the plan.

- Leverages diverse perspectives to identify potential issues.

- Establishes a common language around capacity.

Implementation tip: Hold regular (monthly or quarterly) capacity planning workshops where all stakeholders review historical performance, identify constraints, and collaboratively plan upcoming work.

2. Implement Work In Progress (WIP) Limits

One of the most effective capacity management techniques comes from Kanban:

- Set explicit limits on how many items can be in progress simultaneously.

- Visualize these limits on team boards.

- When a limit is reached, the team must finish in-progress work before starting new tasks.

- Reduce multitasking and context switching.

- Increase completion rates and predictability.

// Sample WIP Limit Implementation in Jira or a similar tool

Backlog: No limit

Ready for Development: 2 items per developer

In Development: 1 item per developer

Code Review: 5 items total

Testing: 3 items total

Done: No limit3. Plan for Different Types of Work

Effective teams explicitly budget capacity for different work categories:

- 50-60% for planned feature development

- 15-20% for bug fixes and technical debt

- 10-15% for unplanned production support

- 10% for learning and innovation

- 5-10% buffer for unexpected issues

This balanced approach creates sustainable delivery while preventing technical debt accumulation.

4. Use Evidence-Based Estimation

Replace gut feeling with data-driven approaches:

- Reference class forecasting: Compare current work to similar past projects.

- Confidence intervals: Use ranges (e.g., “3-5 days”) instead of point estimates.

- Relative sizing: Compare tasks to previously completed work of known size.

- Calibration exercises: Regularly review estimates against actuals.

5. Utilize Capacity Management Software

Modern capacity management software provides crucial visibility and tracking capabilities:

- Real-time dashboards showing current capacity utilization

- Automated tracking of planned vs. actual time

- Early warning systems for potential bottlenecks

- Historical data analysis for estimation improvement

- Integration with existing engineering tools

Workload capacity planning tools like Milestone provide specialized features for engineering teams to visualize capacity, identify bottlenecks, and make data-driven planning decisions.

6. Account for Experience Levels

Recognize that team members have different capacity profiles:

- Junior engineers may take 2-3x longer on complex tasks.

- Senior engineers often have more non-coding responsibilities.

- Mid-level engineers may be most productive in pure coding output.

- Tech leads spend significant time in coordination activities.

Effective capacity models account for these differences rather than treating all team members as interchangeable resources.

In summary, here are the best practices that can be used to achieve effective engineering capacity planning:

- Build multi-functional teams: Develop “T-shaped” skills for flexibility.

- Set up a resource pool: Track availability, skills, and commitments.

- Block out operational time: Engineers can’t code 100% of the time.

- Define clear project roles: Specify responsibilities for each project.

- Prioritize projects: Use frameworks like MoSCoW or RICE scoring.

- Foster communication: Create open channels between all stakeholders.

- Monitor and analyze regularly: Track utilization, progress, and performance.

- Consider capacity planning tools: Upgrade from spreadsheets to specialized software.

Capacity Planning Tools

Designated tools can make the capacity planning process much easier and more effective. Here’s a breakdown of the most common tools for effective capacity planning.

- Basic tools: Spreadsheets like Google Sheets work for simple tracking but become unwieldy with scale.

- Project management tools: Asana, Trello, and Jira help visualize workloads and track progress.

- Engineering management platforms: Specialized platforms like Milestone offer comprehensive features for engineering capacity management.

Wrapping Up

Effective engineering capacity planning remains challenging due to the complex nature of software development. Teams that recognize this complexity and implement evidence-based approaches gain competitive advantages. By avoiding common pitfalls and embracing strategies like collaborative planning, WIP limits, work type budgeting, data-driven estimation, specialized software tools, and experience-level considerations, organizations can transform capacity planning from a frustration point to a strategic asset.